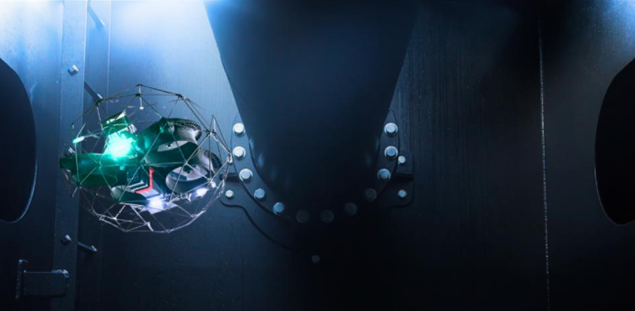

Bureau Veritas Marine & Offshore has introduced the Augmented Surveyor 3D (AGS 3D), an AI- and machine learning-powered tool designed to enhance the detection and localization of anomalies during remote inspections of ships and offshore structures.

As informed, the tool was successfully tested in a pilot project with TotalEnergies on a Floating Production Storage and Offloading unit (FPSO) in West Africa, where drone inspections of water ballast tanks were used to generate detailed 3D digital models enriched with AI-based corrosion analytics.

By taking advantage of drone technology and AI, we can improve critical tasks such as anomaly detection and corrosion mapping and significantly reduce human exposure to risks. As well as increasing the safety of our teams, this also optimizes our maintenance planning and decision-making processes.

… explained Tatiana Akimova, Project Leader at the Innovation Accelerator, TotalEnergies.

AGS 3D streamlines inspections by automating anomaly detection, corrosion mapping, and 3D modeling. This automation reduces the need for human presence in confined spaces and enhances the accuracy of defect localization, supporting more effective maintenance and inspection planning.

As informed, final data outputs, such as 3D models and defect analyses, are reviewed by experts to ensure quality and reliability.

With AGS 3D, we are now able to automatically detect and localize defects, marking a significant step forward in remote inspection technologies and augmented survey. This innovation further supports stakeholders in optimizing asset integrity management and inspection workflows.